- Home

- Machines

Machines

Spark has more than 40 years of experience in the design and production of weaving machines to meet a variety of customer needs. We offer YC air jet looms and JW water jet looms that are known for their exceptional stability, reliability, and cost performance, making our weaving looms the perfect solution for your weaving needs.

-

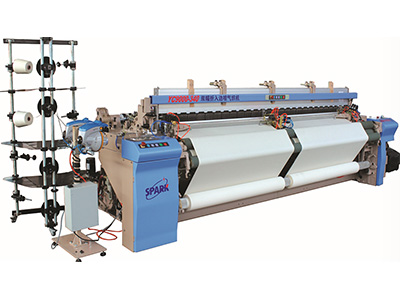

- YC917 Air jet loomThis air jet loom is built to meet the demands of terry fabric weaving, offering a dedicated loop-forming mechanism and a sturdy frame for stable, consistent performance. Commonly used in towels and bath textiles, terry fabrics require precise loop control, which this loom is engineered to deliver with ease.

-

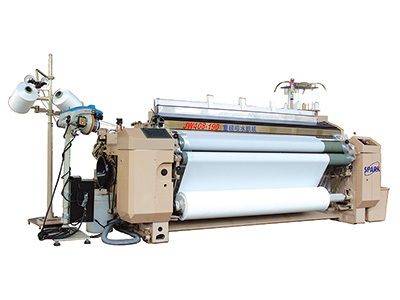

- YC920 Air jet loomThe YC920 ultra-high-speed air jet loom was developed and put into production in 2018 to meet the demands of a new weaving era characterized by high-speed and high-efficiency production of lightweight fabrics.

The YC920 air jet loom features ultra-high weaving speed, high production efficiency, and excellent fabric quality. An eccentric beat-up mechanism is adopted to improve the loom’s balance and running stability, effectively reducing excessive machine vibration during operation and minimizing vibration transmitted to the floor.

-

- YC910 Air jet loomThe YC920 high speed energy saving air jet loom features a maximum rotation speed of 1000RPM, delivering an excellent performance in reducing vibration and air consumption while four weft insertion modes improve the versatility and flexibility of the air jet loom.

This weaving machine has been optimized to greatly improve the rotation speed and uses an eccentric beat-up mechanism to reduce the loom vibration by as much as 35% at high speeds, thereby enhancing the running stability and reliability.

-

- YC9000 Air jet loomThe YC9000 air jet loom is an efficient weaving machine, capable of achieving a high-speed selvedge folding in combination with weaving functions. The fabric selvedge folding unit cuts the woven fabric through the middle, then folds up the four edges to create four smooth and flat hems. The air jet weaving loom features a high working efficiency, stable performance, and precise time control, making it ideal for processing medium-width fabrics. This air jet weaving machine meets the needs of fabrics with complex structures and aesthetics.

-

- YC600 Air jet loomThe YC600 air jet loom is the perfect choice for producing uncomplicated household, apparel and industrial fabrics with a higher output and lower labor cost than a rapier loom or water jet loom. This air jet loom was developed using a water-jet loom for inspiration, and features an air jet weft insertion mechanism, offering the most competitive price in the market and delivering the highest performance in regard to versatility, flexibility and quality.

-

- YC700 Air jet loomThe YC700 air jet loom is a special weaving machine used for the production of glass fiber fabrics. Developed using the YC600 air jet loom as the base, this air jet weaving machine features a durable and stable box-type wall structure and a multi-support weight balanced beating system. To meet the production needs for woven glass fiber fabrics, the back rest has been changed, with a special yarn cutter and air suction device added.

-

- JW8200 Water jet loomThe JW8200 high-speed water jet loom features a higher production efficiency than the JW400 and JW822 water jet looms, with a shift weft density and weaving speed.

The water jet loom features an integrated machine rack, high machine rigidity, advanced electronic control system, stable weft insertion and a beating up mechanism. Four- or six-link crank beating is available.

-

- JW408 Water jet loomSpark’s JW408 water jet loom features an innovated machine structure and moving parts, as well as highly integrated mechanical components and an electronic control system. Compared to the JW822 water jet loom, the JW408 water jet loom’s rotation speed is higher at speeds of up to 900RPM. The water jet weaving machine provides higher versatility and operation functionality for manufacturing light and medium-weight fabrics.

-

- JW822 Water jet loomThe JW822 water jet loom is popular with our international customers as its beating mechanism has been improved to reduce working vibration and noise, while also enhancing overall machine durability and stability. Separating nozzle holders are used to allow for individual settings for the direction and position of each nozzle. The water jet weaving machine is ideal for producing light and medium-weight fabrics with plain, twill, satin or jacquard weaves.

-

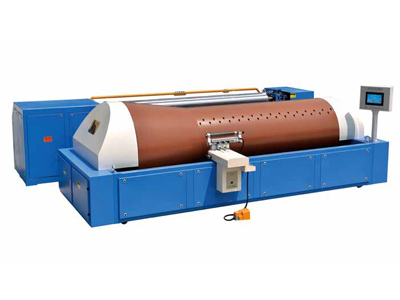

- KGA215H High-Speed Sectional Warping MachineOur high-speed sectional warping machines use a combination of dual servo motors, double linear guide rails, double yarn guide rollers, and ball screws to ensure smooth, accurate control. The beam winding system includes a durable reducer and reinforced support rails, keeping everything stable even at high speeds. This setup works well with both spun and synthetic filament yarns.

-

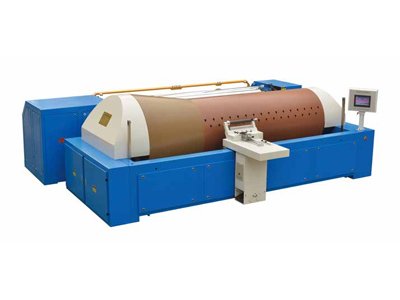

- KGA215C High Speed Sectional Warping Machine and Beaming MachineHigh speed sectional warping machines are suitable for sectional warping of worsted fabrics, high-twist filament yarns, yarn-dyed textiles, silk, terry fabrics, and specialty industrial fabrics. Also ideal as a preparation solution for water jet, air jet, rapier, and projectile weaving machines.

-

- KGA163C High-Speed Sectional Warping Machine and Beaming Machine (Intelligent Type)Ideal for sectional warping of high-end and specialty fabrics, our intelligent high speed sectional warpers can handle a wide variety of yarn types including fine wool, synthetic filaments, dyed yarns, silk, and technical textiles. Designed as a preparation solution for modern weaving methods such as rapier, projectile, water jet, and air jet weaving, it supports flexible production for demanding weaving mills.

-

- KGA163S Sectional Warping Machine (Filament Yarns)This sectional warping machine model features digital controls and a well-integrated structure designed for consistent tension and smooth yarn winding. It’s particularly suited for small-batch sampling and multi-variety production, offering a cost-efficient solution for sectional warping of fine denier and microfiber filament yarns, including sizing applications.

-

- KGA388 Intelligent Sectional Warping Machine (Mother Yarn)This sectional warping machine simplifies the processing of mother yarn by combining slitting and warping into a single step. Yarn is prepared for weaving directly after beaming, shortening the overall workflow and improving efficiency. Consistent yarn tension is maintained throughout the process, ensuring stable performance and quality.

-

- Warp TensionerFront dividing panel: 2mm sheet, ⌀5 alumina ceramic eyelet guide for yarn, and designed with reed at the rear

Guide roller: “W” type, 2 upper guide rollers with ⌀122mm, lower guide roller with ⌀ 122mm

Roller control: Closed-loop control by vector variable frequency motor (constant tension control)

-

- Warping CreelOur upgraded warping creels feature a double-disc without vertical columns that handles a wide variety of yarn types. It is suitable for different warping processes, including sectional and batch warping. Available in rotating rectangular, mobile frame, and compact V-shaped configurations, offering flexibility for various production setups while ensuring consistent and reliable yarn feeding.

-

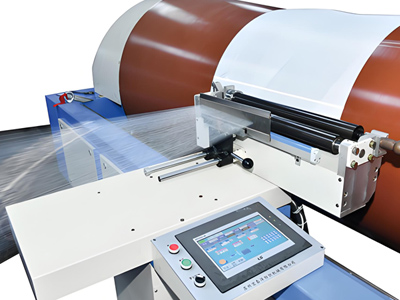

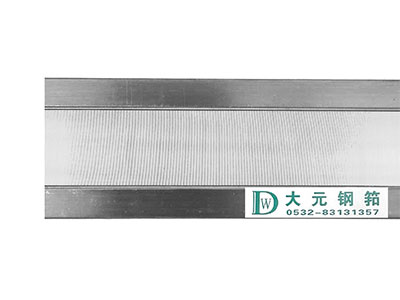

- This water jet loom reed is manufactured by soldering stainless steel dents to stainless steel channels. We also offer custom resin-bonded reeds to meet specific customer requirements.

The reed features a perfectly flat surface, uniform dent spacing, and a polished, smooth finish. Its exceptional wear resistance ensures stable performance and a long service life during high-speed weaving.

Video

- Air Jet Loom

- Water Jet Loom

-

Quick Link

-

Contact Us

- NO.84 Huan Taibei Road, Wangtai Street, Huangdao District, Qingdao,China.

- Ellen Zhou

- +86-18353204512

- sweeti.e@163.com