- Home

- Machines

- Warping Machines

- KGA163C High-Speed Sectional Warping Machine and Beaming Machine (Intelligent Type)

KGA163C High-Speed Sectional Warping Machine and Beaming Machine (Intelligent Type)

Ideal for sectional warping of high-end and specialty fabrics, our intelligent high speed sectional warpers can handle a wide variety of yarn types including fine wool, synthetic filaments, dyed yarns, silk, and technical textiles. Designed as a preparation solution for modern weaving methods such as rapier, projectile, water jet, and air jet weaving, it supports flexible production for demanding weaving mills. Their precise control and high-speed performance make our sectional warping machines suitable for warping high quality fabrics, delicate materials, and textiles that require high tension and accuracy during the warping process.

Features

- Both the warping and beaming drives use AC frequency conversion for constant surface speed, stable yarn tension, and high-speed operation.

- Integrated electro-hydraulic-pneumatic system controls braking via caliper brakes, while a precision proportional valve manages yarn tension through a steel-band damping system for automatic beaming tension control.

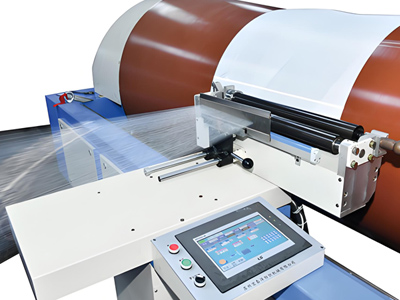

- The warping table is powered by a dual-servo motor and ball screw structure, enabling fast response and high positioning accuracy. Stripe and start-point positioning are completed automatically with a single touch.

- Servo-driven forward and backward movement of the warping table is controlled by AC digital drives and ball screws. Equipped with yarn pressing rollers and multiple sensors.

- During warping, the table moves back at equal intervals, maintaining consistent yarn layer quality.

- Layer thickness is measured in real-time with a laser sensor, and the servo-driven table adjusts displacement accordingly. The yarn pressing roller ensures a flat and even yarn surface.

- The warping drum is dynamically balanced to ensure smooth and stable operation throughout the high-speed warping process.

- The entire system uses advanced communication and automation technology with integrated PLCs, digital AC servo inverters, dual touchscreens, and centralized control of electrical, pneumatic, and hydraulic functions.

- The main warping unit moves along floor rails, while the leasing stand and creel remain fixed, keeping the yarn tape centered and maintaining uniform edge tension.

- The mobile beam winder can be shared across multiple warping units and connects via quick electrical and pneumatic plugs; it can also be fixed for single-machine use.

- Various creel configurations available; spindle pitch and number can be customized.

- Optional accessories include multiple types of tensioners, yarn break sensors, and anti-static devices on the warping table.

- The beam winder is equipped with an oiling unit for waxing or lubrication during winding.

Machine specifications

| Working width | 230~4800mm | Section traverse accuracy | 0.02% |

| Beam flange diameter | 800, 1000, 1250mm | Section width | 0.1~400.0mm |

| Warping speed | 0~800m/min | Control panel for warping | 10.4 inch color touchscreen |

| Beaming speed | 0~200m/min | Control panel for beaming | 10.1 inch color touchscreen |

| Beaming tension accuracy | ≤±2% | Spindle space | 250x250(mm) (wool, cotton yarn, blended yarn) 290x290(mm) (chemical fiber filament) |

| Braking distance | ≤3(m) (500m/min) | Input voltage | 3x380V(±10%) |

| Beaming tension | ≤8000N | Installation capacity | 40, 50kVA |

| Drum diameter | 1026mm | Warping motor power | 11, 15kW |

| Cone Length | 1010, 1360mm | Beaming motor power | 15, 22kW |

| Cone angle | 1:6.3=9° 1:8=7.125° | Warping and beaming machine weight | 5500kg |

| Section traverse speed | 0.00~9.999mm/r (stepless) | Creel weight | 2500kg |

| Section positioning accuracy | ≤0.1mm | |

- Air Jet Loom

- Water Jet Loom

-

Quick Link

-

Contact Us

- NO.84 Huan Taibei Road, Wangtai Street, Huangdao District, Qingdao,China.

- Ellen Zhou

- +86-18353204512

- sweeti.e@163.com