- Home

- Machines

- Air Jet Loom

- YC917 Air jet loom

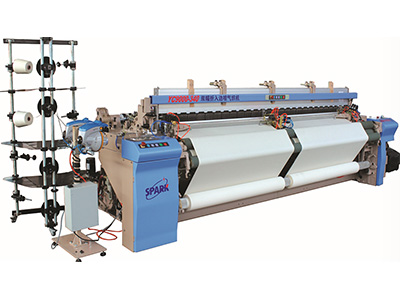

YC917 Terry Towel Air jet loom

This air jet loom is built to meet the demands of terry fabric weaving, offering a dedicated loop-forming mechanism and a sturdy frame for stable, consistent performance. Commonly used in towels and bath textiles, terry fabrics require precise loop control, which this loom is engineered to deliver with ease.

Features

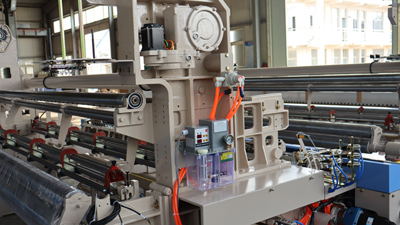

- The frame is reinforced with sealed box-type side panels that are thicker and heavier than standard designs, providing better support and minimizing vibration during high-speed operation and loop formation. Four square-section braces at the base enhance structural rigidity, while the improved upper warp beam configuration offers added stability.

-

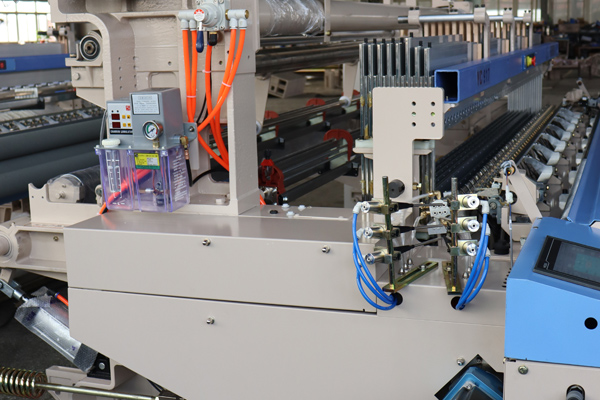

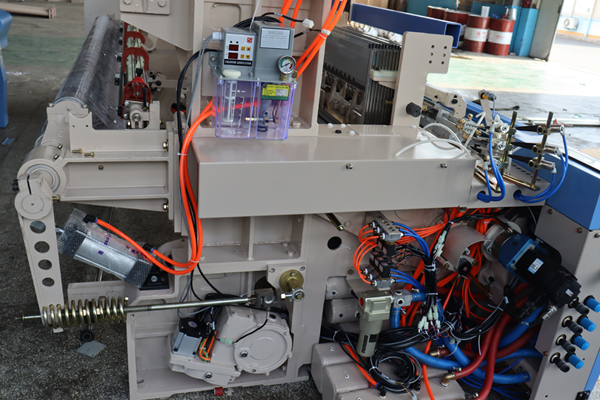

The upper warp beam loading is simplified thanks to a patented pneumatic flipping system on the rear support of the bottom warp beam. With a simple switch control, the beam is automatically lifted, allowing the warp beam to be inserted easily, there’s no need to remove covers or lift anything manually, making setup faster and less physically demanding.

-

The air circuit has been reconfigured to include a front-end air reservoir before distribution. This added air storage capacity helps maintain more stable pressure, which significantly reduces pressure drops during startup and operation. Compared to conventional setups, it offers better pressure consistency and improves overall energy efficiency by lowering compressed air consumption.

Machine specifications

| Item | Configurations | Options | ||

| Reed width | Nominal | 190, 210, 230, 260, 280, 340, 380 (cm) | ||

| Effective | -80~0 (cm) | |||

| Weft selection | 2, 4, 6 Colors | |||

| Motor | Start mode | Direct on-line super-start | ||

| Power | 3.7kW (Dobby shedding ) | |||

| 5.5kW( Jacquard shedding) | ||||

| Operation | Two-hand button control, jogging with VFD | |||

| Picking | Main & Sub nozzle | Stretch nozzle | ||

| Sub main nozzle | Weft brake system (2C)/WBS | |||

| Picking control | One nozzle for three-weft insertion | One nozzle for 2-weft insertion | ||

| Automatically control the insertion of the first weft yarn | ||||

| Weft insertion length control | Electric control weft feeder | Anti-Air loop device | ||

| Selvedge | Yarn twisted edge | Tuck-in device | ||

| Weft cut | Left side: mechanical; right: Electric | |||

| Lubricating | Main transmission: oil bath lubrication; others: Centralized lubrication by manual grease pump | Electric grease pump | ||

| Stopping | Weft stop | Photoelectric weft sensor with dual probe | Weft sensor with triple probes | |

| Wrap stop | Electric 2 row 2 column warp shafts | |||

| Others | Auto stop after detecting selvedge yarn breakage, and waste yarn | |||

| Sign for stop | Multi-functional 4-color indicator light for displaying stop status | |||

| Beating | Multi-support eccentric weft beating | |||

| Controlled seven-linkage beating system | ||||

| Shedding | Electric Dobby 16 heald frames | |||

| Electric Jacquard | ||||

| Let-off | Upper & down dual beam electric let-off | |||

| Terry motion mechanism control | ||||

| Terry setting length control | ||||

| Warp beam disc dia.: ⌀800mm Terry warp disc dia.: ⌀914mm | ||||

| Take-up | Electric take-up with stopping and empty weaving function | |||

| Weft density range: 25-300 pcs/inch | ||||

| Count by towel rows and show on digital display | ||||

| Max. roll diameter (inside): ⌀600mm | Max. roll diameter (outside): ⌀1500mm | |||

| Loop formation device | "Reed action" pile loop device | |||

| Servo motor controlled pile loop height | ||||

| Single-side pile loop height up to14mm, dual-side up to 28mm | ||||

Inquiry

- Air Jet Loom

- Water Jet Loom

-

Quick Link

-

Contact Us

- NO.84 Huan Taibei Road, Wangtai Street, Huangdao District, Qingdao,China.

- Ellen Zhou

- +86-18353204512

- sweeti.e@163.com