Warping Machines

-

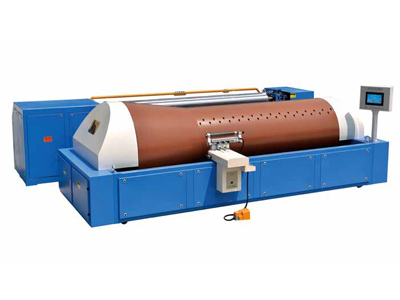

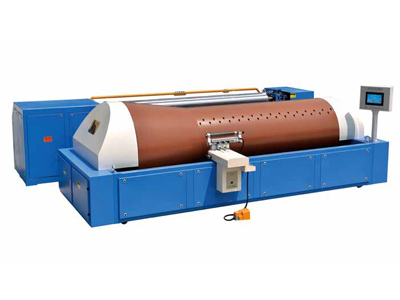

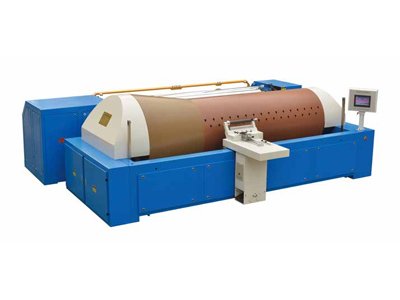

- KGA215H High-Speed Sectional Warping MachineOur high-speed sectional warping machines use a combination of dual servo motors, double linear guide rails, double yarn guide rollers, and ball screws to ensure smooth, accurate control. The beam winding system includes a durable reducer and reinforced support rails, keeping everything stable even at high speeds. This setup works well with both spun and synthetic filament yarns.

-

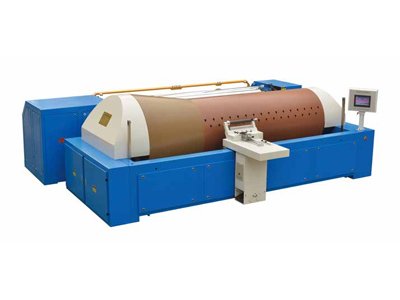

- KGA215C High Speed Sectional Warping Machine and Beaming MachineHigh speed sectional warping machines are suitable for sectional warping of worsted fabrics, high-twist filament yarns, yarn-dyed textiles, silk, terry fabrics, and specialty industrial fabrics. Also ideal as a preparation solution for water jet, air jet, rapier, and projectile weaving machines.

-

- KGA163C High-Speed Sectional Warping Machine and Beaming Machine (Intelligent Type)Ideal for sectional warping of high-end and specialty fabrics, our intelligent high speed sectional warpers can handle a wide variety of yarn types including fine wool, synthetic filaments, dyed yarns, silk, and technical textiles. Designed as a preparation solution for modern weaving methods such as rapier, projectile, water jet, and air jet weaving, it supports flexible production for demanding weaving mills.

-

- KGA163S Sectional Warping Machine (Filament Yarns)This sectional warping machine model features digital controls and a well-integrated structure designed for consistent tension and smooth yarn winding. It’s particularly suited for small-batch sampling and multi-variety production, offering a cost-efficient solution for sectional warping of fine denier and microfiber filament yarns, including sizing applications.

-

- KGA388 Intelligent Sectional Warping Machine (Mother Yarn)This sectional warping machine simplifies the processing of mother yarn by combining slitting and warping into a single step. Yarn is prepared for weaving directly after beaming, shortening the overall workflow and improving efficiency. Consistent yarn tension is maintained throughout the process, ensuring stable performance and quality.

-

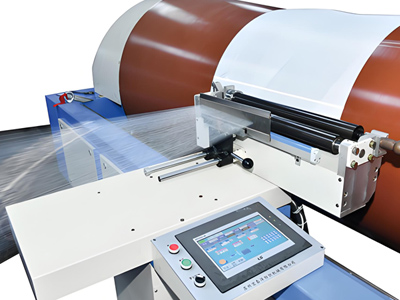

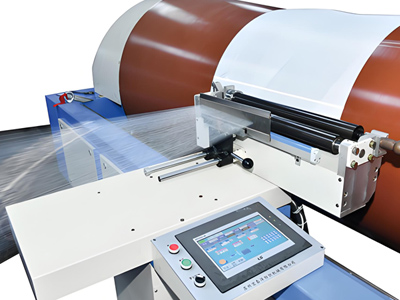

- Warp TensionerFront dividing panel: 2mm sheet, ⌀5 alumina ceramic eyelet guide for yarn, and designed with reed at the rear

Guide roller: “W” type, 2 upper guide rollers with ⌀122mm, lower guide roller with ⌀ 122mm

Roller control: Closed-loop control by vector variable frequency motor (constant tension control)

-

- Warping CreelOur upgraded warping creels feature a double-disc without vertical columns that handles a wide variety of yarn types. It is suitable for different warping processes, including sectional and batch warping. Available in rotating rectangular, mobile frame, and compact V-shaped configurations, offering flexibility for various production setups while ensuring consistent and reliable yarn feeding.