- Home

- Machines

- Air Jet Loom

- YC700 Air jet loom

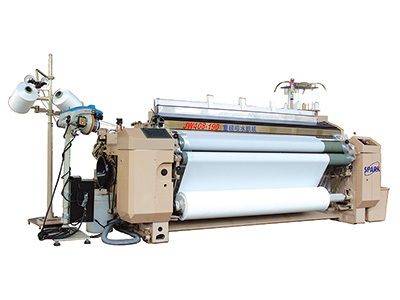

YC700 Air jet loom

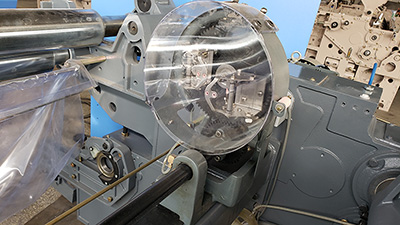

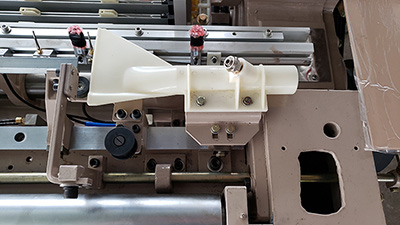

The YC700 air jet loom is a special weaving machine used for the production of glass fiber fabrics. Developed using the YC600 air jet loom as the base, this air jet weaving machine features a durable and stable box-type wall structure and a multi-support weight balanced beating system. To meet the production needs for woven glass fiber fabrics, the back rest has been changed, with a special yarn cutter and air suction device added. The air jet weaving machine is suitable for the production of thermal insulation material, fire-proof cloth, insulated PCB substrate, etc.

Features

- The back rest has been altered to meet glass fiber weaving needs.

- A special yarn cutter and an air suction device have been added.

- The high-speed response solenoid valve and optimized air jet control system are equipped to reduce the air consumption by 35%.

- The high-speed weft insertion system consists of a TOYOTA 810 main nozzle, swing nozzle and sub nozzle.

- Different take up and let off options are available to meet different customer production requirements, including electronic let off, electronic take up, mechanical let off and mechanical take up. For the shedding mechanism, crank shedding, cam shedding, dobby shedding or electronic jacquard shedding are optional.

Machine specifications

| Item | Specifications | Spare Parts | |

| Reed Width | Nominal | 150, 170, 190, 210, 230, 250, 280, 340, 360, 390 | |

| Effective | Nominal: 0~60cm (150-250) 0~80cm (>280) | ||

| Weaving Range | Glass fiber | ||

| Weft selection | 1, 2, 3, 4 & 6 Colors | ||

| Motor | Start mode | Super speed start | |

| Press the start/stop button to slow action forward/rear | |||

| Press the link& start button at the same time to start | |||

| Power | 2.8kw, 3.0kw, 3.7kw, 4.5kw, 5.5kw | ||

| Weft insertion | Method | Main nozzle+ Swing Nozzle+ Sub nozzle+ U type reed | WBS(Weft brake system) |

| Control | Import high frequency sub nozzle/ computer program control | ||

| Sub nozzle | Integrated flow sub nozzle | ||

| Feeder | Electric control loop feeder | Balloon prevent device | |

| Beating | Beating motion | Dual oil bath box type 4-bar/ 6bar/ eccentric beating motion | |

| Solid beating system | |||

| Multi support brick and balance weight | |||

| Shedding | Crank/ Plain shedding | ||

| Cam shedding | |||

| Electronic Jacquard shedding | |||

| Dobby Shedding | Upper dobby shedding | ||

| Let Off | Electric servo let off | Double Warp Beam | |

| Dual back beam | |||

| Positive/ negative let off | |||

| Flange dia. | 800, 914, 1000 mm | ||

| Take up | Take up | Electric servo/ mechanical take-up | |

| Fabric rolling | Inside rolling (Max. 600mm)/ Outside rolling | ||

| Temple | Upper/ underneath | ||

| Selvedge | Dual sides planet selvedge/ electric | ||

| Lubrication | Motion box is oil bath, others are centralized lubricating | ||

| Shut down device | Weft breakage | Reflecting double sensor W1, W2 | |

| Warp breakage | Control system warp break detector, LED display | ||

| Others | Selvedge yarn/ yarn end break stop motion | ||

| Shutdown display | Screen display, multi- function shutdown display lights | ||

| Weft cutter | Mechanical cutter, electronic cutter | ||

| Electric control system | High resolution large VGA color touch display, DSP motherboard, WIFI connect. | ||

Inquiry

- Air Jet Loom

- Water Jet Loom

-

Quick Link

-

Contact Us

- NO.84 Huan Taibei Road, Wangtai Street, Huangdao District, Qingdao,China.

- Ellen Zhou

- +86-18353204512

- sweeti.e@163.com