- Home

- Machines

- Warping Machines

- KGA215C High Speed Sectional Warping Machine and Beaming Machine

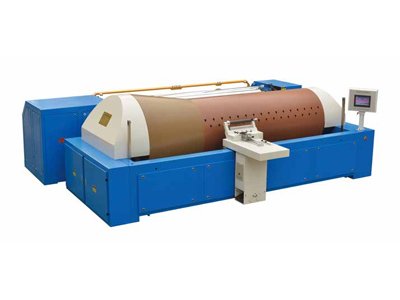

KGA215C High Speed Sectional Warping Machine and Beaming Machine

High speed sectional warping machines are suitable for sectional warping of worsted fabrics, high-twist filament yarns, yarn-dyed textiles, silk, terry fabrics, and specialty industrial fabrics. Also ideal as a preparation solution for water jet, air jet, rapier, and projectile weaving machines.

Features

- The warping table’s axial positioning is controlled by a high-precision servo motor, enabling automatic start point and stripe alignment with a single command.

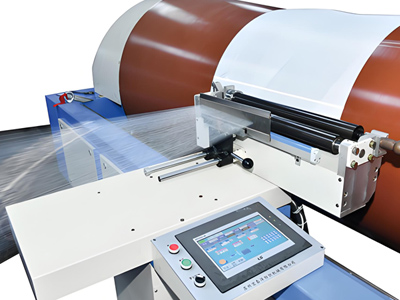

- Radial movement is managed by an independent stepper motor, allowing consistent spacing between the width reed and yarn surface. The distance can be freely set according to production needs.

- Equipped with advanced variable frequency drive (VFD) control, maintaining constant yarn surface speed on the drum during winding and unwinding.

- A specialized integrated system combining mechanical, electrical, hydraulic, and pneumatic components generates stable oil pressure for braking. The tension during beam winding is regulated by an external steel belt damping system, which minimizes noise and ensures more consistent tension, avoiding the common issues seen with traditional clamp-style mechanisms. (Optional automatic tension control systems are also available upon request.)

- The intelligent control system, controlled through a PLC and computer interface, provides real-time monitoring with features such as length counting, stripe positioning, yarn break memory, and automatic stopping when preset lengths are reached or yarn breaks occur.

- Features a large touchscreen interface for clear display, real-time information, and intuitive operation.

- The main drum is servo-driven along ground rails, while components such as the leasing reed and creel remain stationary, ensuring a straight yarn path and consistent tension during warping.

- A robust steel cone drum combined with a precision-controlled warping table allows compatibility with a wide range of fabric types and warping requirements.

- Optional beam winding units are available in both mobile and fixed types. The mobile type can serve multiple warping stations and be configured with waxing, oiling, or beam pressing features, while fixed types offer a more compact and user-friendly setup.

- Various creel setups are available to suit different yarn types, with customizable spindle spacing and capacity.

- Supports a range of tensioner types including dual-post, triple-post, and hanging ring tensioners.

- Comes standard with yarn break detectors and static eliminators to maintain quality and safety during operation.

Main specifications

| Working width | 2300~4800mm (could be made upon request) |

| Beam flange diameter | 800, 1000, 1250mm |

| Warping speed | 0~600m/min |

| Beaming speed | 0~100m/min |

| Deviation of linear speed (warping & beaming) | ±2% |

| Braking distance | ≤ 2m (at the speed of 300m/min) |

| Beaming tension | ≤ 6000N (at the beaming speed ≤50m/min) |

| Drum diameter | 1026mm |

| Cone Length | 1010mm |

| Cone angle | 9° |

| Section traverse speed | 0.001~9.999mm/r (stepless) |

| Section traverse accuracy | 0.02% |

| Distance between reed and drum | Adjustable |

| Positioning of cone starting point | Automatic |

| Section positioning | Automatic |

| Section width | 0.1~999.9mm (The length should not be longer than the guide roller) |

| Spindle space | 250x250, 280x280mm (could be made upon request) |

| Spindle numbers | 640, 720, 800, 960 ends (could be adjusted upon request) |

| Input voltage | 3x380V(±10%) |

| Installation capacity | 30kVA |

| Warping motor power | 7.5kW |

| Beaming motor power | 15kW |

| Section traverse motor | 1.5kW |

| Warping and beaming machine weight | 4500kg |

| Creel weight | 2500kg |

- Air Jet Loom

- Water Jet Loom

-

Quick Link

-

Contact Us

- NO.84 Huan Taibei Road, Wangtai Street, Huangdao District, Qingdao,China.

- Ellen Zhou

- +86-18353204512

- sweeti.e@163.com